Our previous boat, Ocean Mist, had a fairly typical boat electrical system of a 200AH domestic battery bank and a 100AH starter battery charged through a split charging relay from the standard engine alternator. When we spent a summer living aboard we quickly found that this wasn't adequate for extended use when we weren't able to plug into shore power on a regular basis. As we bought Speedwell of Rhu specifically for extended independent cruising, and when we bought her she had rather old looking batteries, we decided to completely update the electrical system.

Batteries

Domestic Bank

Within reason the bigger a domestic battery bank can be the better. A bigger bank will allow longer periods between charges and will accept more current when it is on charge. Also the capacity of a lead acid battery depends on the discharge rate compared with the battery capacity (the higher the ratio the lower the capacity), a given load will be a lower relative discharge rate from a bigger bank giving a further increase in available capacity.

Authorities on boat electrical systems recommend sizing a battery bank by working out what the various loads are, how long they're going to be used each day and how many days there will be between recharging the batteries. I think that's all very well in theory but in practice our electrical use and the time spent between engine running has been highly variable so I don't think I could have come up with a reliable estimate before actually using the system, which is why we went for the largest practical installation.

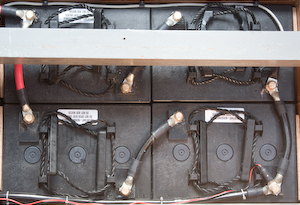

Our domestic battery bank consists of four 300AH 6V Lifeline AGM batteries in a series/parallel configuration giving 600AH at 12V. This upgraded the domestic capacity from the original 400AH.

Although more expensive than flooded cell batteries AGMs have the advantage of a very low self discharge rate so they can be safely left unconnected for anything up to a year between charges. We have been be laying Speedwell up in different locations each year and haven't been able to guarantee what facilities are available at each place be so being able to leave the boat without needing to arrange shore power to float charge the batteries has been a real advantage for us. If we were living aboard permanently then good quality flooded cell batteries would have been a more economical choice.

The specific model of battery that we chose was determined by the space available. The Lifeline batteries have almost exactly the same width and depth as the ones they were replacing but were taller (just able to fit in the height we had in the battery space). Because of slight differences in the horizontal dimensions it was necessary to build a new battery box, this just squeezes in so the batteries aren't going to move around.

In the event of a short circuit AGM batteries can deliver very large currents, our domestic bank could deliver well over 1000A, so it is important to fuse the circuit. A 400A class T fuse next to the battery box protects our domestic supply.

Starter Battery

As with the domestic bank we've fitted an AGM starter battery, again this is so that we can lay the boat up without having to have a shore supply for float charging. We fitted a 68AH Odyssey micro engine start battery. This is a smaller capacity than the flooded cell battery that it replaces, although on our heavy cruising boat the weight saving isn't significant (especially as we've added weight in the domestic bank). A starter battery is sized for the current it can deliver for a short period rather than its overall capacity and the higher output current of an AGM battery allows a smaller capacity one to be fitted.

The starter battery is also fused with a 400A class T fuse. According to the workshop manual our engine's starter motor can take up to 900A, which on the face of it exceeds the fuse rating. However 400A is the fuse's continuous rating and engine starting only takes a few seconds, over shorter periods it takes proportionally more current to blow the fuse and 900A for a few seconds is within the fuse's rated capacity.

Charging

There's no point fitting a large battery bank if you can't re-charge it in a reasonable time. We aim to be independent of shore power so we had to have sufficing charging capacity to cope with our upgraded bank. We don't have a separate generator set so our primary charging source is the main engine.

Alternators

We've fitted a Balmar 150A alternator in place of the old engine driven fridge compressor. This is in addition to the existing engine alternator. The twin alternator set-up allows us to isolate the engine and domestic electrical systems without using an isolator or split charging relay and gives a back-up charging option should one of the alternators fail. The original engine alternator charges the starter battery, the new alternator charges the domestic bank and the two circuits are completely independent (apart from an emergency parallel switch).

The domestic bank will generally be in a very different state of charge to the starter battery (which should never get discharged very far) so the two alternators can each charge at the appropriate voltage for their batteries' current state of charge.

The Balmar alternator is controlled by a Balmar Maxcharge multi-stage regulator so that the domestic bank is charged efficiently. The engine charge alternator uses its built in regulator as there's no need for clever charging regimes for a battery that is only ever lightly discharged.

The engineering department at Fox's made up a pulley and brackets to mount the Balmar alternator. We've sized the pulley so that the alternator can deliver its full rated output from an engine speed of around 1200RPM, so that we don't need to run the engine at high revs if we're just running it for charging. It's best not to run a diesel engine at light loads for extended periods but with a high alternator output when we do need to run the engine just for charging we don't need to run it for too long. Our high output alternator needs something like 5HP to drive it at full load once all of the mechanical losses are included so at least it's putting some load on the engine. In fact we've found that the high alternator output means that the batteries are generally charged during normal engine running so we've only had to run the engine just for battery charging for a couple of hours in a full season.

Mains Charger

A 50A Victon Phoenix charger provides battery charging when we're on shore power. Although this is a multi-output charger it's only connected to the domestic bank as there are no loads on the starter circuit when we're in a marina so there's no need to charge that battery (leaving a battery on continuous float charge can shorten its life and our AGM batteries can hold their charge for many months so it's better left alone). If, for some reason, we do need to charge the starter battery in a marina we can use the emergency parallel switch to connect it to the domestic circuit.

The charger accepts a mains input of anything from 90V to 265V giving us the option of using it in combination with our inverter to give a European mains supply onboard anywhere in the world.

Renewables

We have (or had, see below...) wind and solar generating capacity on the boat.

Wind Generator

During the re-fit we had our Rutland 913 wind generator fitted on the mizzen mast, but in the following year it failed in strong winds. Here's the story.

Solar

We originally fitted two GB-Sol 18W solar panels to the coach roof over the deck saloon. The choice here was determined by the available space, different manufacturers make their panels in different shapes and the GB-Sol panels were the highest output that happened to fit our coach roof.

The output of a solar panel is significantly reduced by even a small amount of shading. If two panels are connected together and one is shaded the output from the unshaded panel is pulled down as well so that overall the installation behaves as if each panel were shaded. Our panels are either side of the coach roof so it's quite likely that one will be in shade (from the boom for example) while the other is in full sun. To allow for this the two panels are independently regulated, so each is able to give its best output.

We've fitted a small maximum powerpoint tracking (MPPT) solar regulator to each panel, these are then wired in to the domestic battery bank. An MPPT regulator is more expensive than a pulse width modulated regulator, but it is able to extract more power from the panel (up to 30% more) and as our installation is limited by space rather than cost the extra expense was worthwhile.

On a sunny day in Scotland with one panel in full sun and one in shade our installation delivers just over 1A.

Subsequently we fitted 3 100W panels on our pushpit. These significantly increased our renewable energy generating capacity, more than making up for the loss our our wind generator. For details of our upgraded system and our experiences with is see our article on solar charging.

Monitoring

In order to get the best out of an electrical system, make decisions about what loads can safely be run and decide when to re-charge the batteries some sort of battery monitoring is essential. We've fitted a Victron BMV602 battery monitor, this measures current in/out and voltage for the domestic bank and voltage only for the starter battery. The monitor is programmed with the domestic bank's size and characteristics so that it can estimate the state of charge (allowing for charging efficiency and the effects of different rates of discharge), that gives us a “fuel gauge” for the batteries.

On our previous boat we just had a voltmeter for each battery bank. The battery voltage with no load is a good indication of state of charge, but to make an accurate estimate it's necessary to leave the battery with no load for an hour or so to settle down and this is impractical when living on a boat (for example, we leave our fridge on all the time we're aboard). Our experience with the battery monitor is that it appears to give a reasonably good estimate of the state of charge and that this ties in with the time the alternator regulator spends at its various charging voltages.

Speedwell was originally fitted with a battery monitor that simply integrates charge in or out of the batteries. We've recycled this as a renewable energy monitor so it now measures current from the solar panels and counts up the ampere-hours delivered. This gives us some information about how the renewables are behaving, largely for interest.

Electrical Loads

The batteries and charging system are one side of the electrical equation on a boat, on the other side are the systems that consume power. Efficient electrical systems contribute as much to time between re-charging as the size of the battery bank. We've upgraded some of the systems on Speedwell to improve their efficiency.

Lighting

Each interior light was already individually switched and most of the cabin lighting was efficient low voltage fluorescents when we bought the boat so we were starting from a good base. We've changed the reading lights and wall lights in the saloon from incandescent to LED units, both to improve efficiency and to replace what we through were some rather tasteless old brass fittings (we ended up spending rather more than we'd anticipated on these lights, they were one of our extravagances).

The masthead tricolour has been replaced with an Aquasignal LED unit. As well as reducing power consumption when sailing at night an LED unit should be more reliable than an incandescent bulb so we're hoping that this will help to reduce trips to the masthead. We have also replaced the deck level navigation lights with LED units, again mainly for reliability.

Refrigeration

Speedwell originally had a fridge in the galley and a large chest freezer under one of the saloon seats. An engine driven compressor ran holding plates in the fridge and freezer and an electrically driven compressor provided alternative cooling for the fridge. After 20 years in service the engine driven system wasn't working and rather than repairing it we removed it.

We removed the freezer. A freezer can easily become the master of a small boat. It's not safe to defrost then re-freeze food so the freezer has to be kept cold all of the time which can become the deciding factor of when to run the engine. Removing the freezer has given us a large locker that can potentially hold a lot of tins and dried food.

We replaced the electrical fridge compressor with a new keel cooler system from Penguin. The keel cooler is more efficient than an air cooled system and is quieter in operation. We leave the fridge on all of the time. The combination of an efficient system with our upgraded batteries and charging systems means there's no need to run up and down the companionway steps to turn the fridge on and off when the engine is started and stopped and we've always got a cold beer ready to celebrate arriving at a new destination.

Mains Electricity

Our electrical system is set up to be independent of shore power so we have to generate our own mains electricity, for which we've fitted a 1.5kVA pure sine wave inverter from Sinergex. Several suppliers sell inverters that look identical to ours, with identical specifications but with different labels, so I suspect that these all come out of the same factory somewhere in the far east.

We generally use the inverter to supply mains to re-charge various portable appliances. When we're running the inverter we try to have as many things recharging as we can to make best use of the system, although we can comfortably run it for several hours a day to power our laptop.

The mains output is connected through a selector switch to the boat's ring main. If we're on shore power we can switch the ring main over to the shore supply.

Although the inverter has an option for remote control we've not fitted this and just turn its 12V input on and off as required, so we know that it's not taking any current when we're not using it. The inverter is fitted in a locker close to the domestic battery bank to keep the heavy current 12V wiring as short as possible. The 12V input is via a heavy duty isolator switch and the mains output runs through an RCD circuit breaker.

The inverter is large enough to run a small electric kettle (we've got a 1.5kW kettle that was advertised as as low energy use) or our portable induction hob. The induction hob is rated at 1.8kW full power, the inverter has a short term rating of 1.8kVA so it will run the hob for a few minutes at full power, after which we'd normally be turning it down to simmer anyway. Boiling a kettle or cooking a meal takes a reasonable amount of charge from the batteries (between 5 and 10% for a stew in the pressure cooker). In sunny weather at anchor our upgraded solar panels are able to keep up with this load, but in more cloudy weather or when we're under way we still need to use the gas stove. I like the idea of using an all electric galley to remove the need to carry gas on the boat but I think a generator set would be needed to keep up with the load.

Experiences

We've sailed Speedwell to various places from the Shetland Islands to southern Spain, living abroad for extended periods. During summers we've spent most of our time at anchor, so most of the time we haven't had shore power available. The electrical system has coped very well.

We have mains power to run our laptop and recharge things like our electric outboard motor, and we can run the inverter for several hours a day.

The high output alternator coupled with batteries that will accept high charging rates has been the most important part of the upgrade. Given the amount of time we've been on shore power a lower specification mains charger would have sufficed.

A small amount of engine running at the start of the day leaving an anchorage and at the end of the day entering a new anchorage is normally sufficient to charge the batteries and the occasional few hours of motor sailing that just happen in the normal course of things will bring the batteries up to 100% charge and give them some float charging.

The upgraded solar power system has allowed us to stay at anchor for as long as we have wanted to without having to run the engine for battery charging.